ARTICLE : Laser etching eco-friendly process

● Dry etching process:using laser beams directly to make dry etching, different from conventional wet complicated photolithography.

● The dry etching process applied on the conductive layers, including the transparent conductive material and silver paste, removes the conductive layer with laser to achieve the aim of pattern transfer.

● It is a non-masked process, featuring reduced costs, fast sample making and shortened development cycle.

● It is also a one-step eco-friendly process with fast, low-temperature and energy-saving advantages.

Circuit design | Wet etching – Photolithography | |||||

photoresist coating | Exposure | Develop-ing | Drying | Etching | Stripping | |

- Masking is costly

- Chemical material supplying central system is required

- Waste fluid treatment system is required

- Complicated process – High-cost energy consumption

| Circuit design | Dry etching – Laser etching |

- No masking cost

- No need of central supplying system, no waste fluid

- Single process – Environment protecting and energy saving

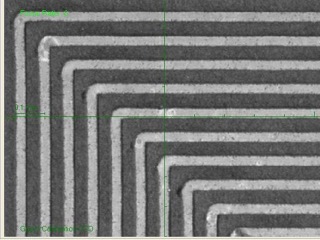

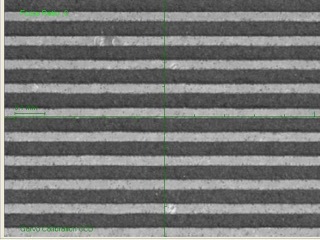

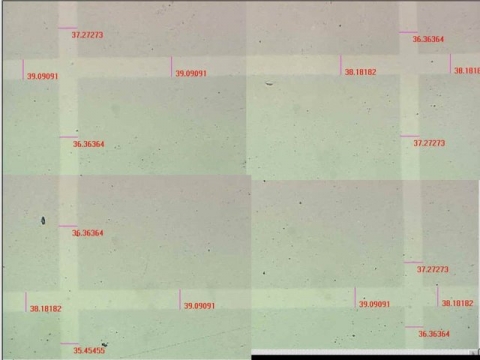

Optical microscope photo of silver wire layout

Laser etching technology can be applied on the transparent conductive layer, which is a simple yet stable and fast process.